ARC FLASH SUIT

Introduction

- Cause: Triggered by mechanical breakdowns, circuit failures, current overloads, or accidental contacts.

- Explosive Energy: Releases electromagnetic energy, plasma, and molten metal.

- Extreme Temperatures: Can reach up to 35,000°F, four times hotter than the sun’s surface.

- Molten Copper: Generated during the event, often exceeds 2,000°F.

- Rapid Expansion: Molten metal and plasma can spread far from the arc source.

- Serious Risk: Poses severe injury or death to anyone nearby.

- Necessity of Protection: Proper protective measures are crucial to avoid devastating consequences.

Benefits

1.Worker Protection: Safeguards workers from severe injuries related to electrical hazards and arc flashes.

2.Compliance: Ensures adherence to OSHA regulations and NEC standards, minimizing legal and financial risks for employers.

3.Thermal Hazard Defense: Arc-rated clothing provides critical protection against the extreme heat and thermal energy generated by arc flashes.

4.Flame Resistance: Prevents clothing from igniting, reducing the risk of burns and injuries.

5.Regulatory Assurance: Products comply with ASTM and ANSI standards, guaranteeing high safety and performance.

6.Enhanced Safety Culture: Promotes a safer working environment, reinforcing the importance of proper PPE usage among employees.

Completing an Arc Flash Hazard Analysis

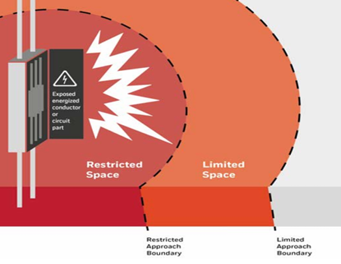

1.Determine the Arc Flash Boundary: Calculate the boundary at 1.2 calories/cm², where a worker without PPE would receive 2nd degree burns. Identify limited and restricted approach boundaries, requiring proper training and PPE for workers.

2.Decide on Required PPE: Select appropriate personal protective equipment based on the specific arc flash hazard.

3.Label Equipment: Mark electrical equipment with:

- Normal system voltage

- Arc flash boundary

- Incident energy, minimum arc rating of clothing, and/or site-specific PPE level.

Applicable Standard/Requirements

1.NFPA 70E :- Standard for electrical safety in the workplace

2.ASTM F1506 :- Standard performance specification for f lame resistant and electric arc rated protective clothing worn by workers exposed to flames and electric arcs

3.ASTM F1959/F1959M :- Standard test method for determining the arc rating of materials for clothing

4.ASTM F2178 :- Standard test method for determining the arc rating and standard specification for eye or face protective products

5.ANSI Z87.1 :- Standard for occupational and educational personal eye and face protection devices.